|

Back to

ZapKites folder in our site ****** ENDLESS

LOOP SPOOL AND GENERATOR DESIGN by Brooks Coleman ******

See first:

M988 in open forum :

Re: [AWECS] Challenge: Dynamic length-variable power-transferring

endless-loop conveyor

This is the method I have been working on. It is meant as a method to

transfer the mechanical energy from any rotating pulley system to the

ground via and endless loop of variable length. The length of the loop can

be changed while in operation.

I'll post an animation of the device in operation when time permits.

-brooks

23jan2010

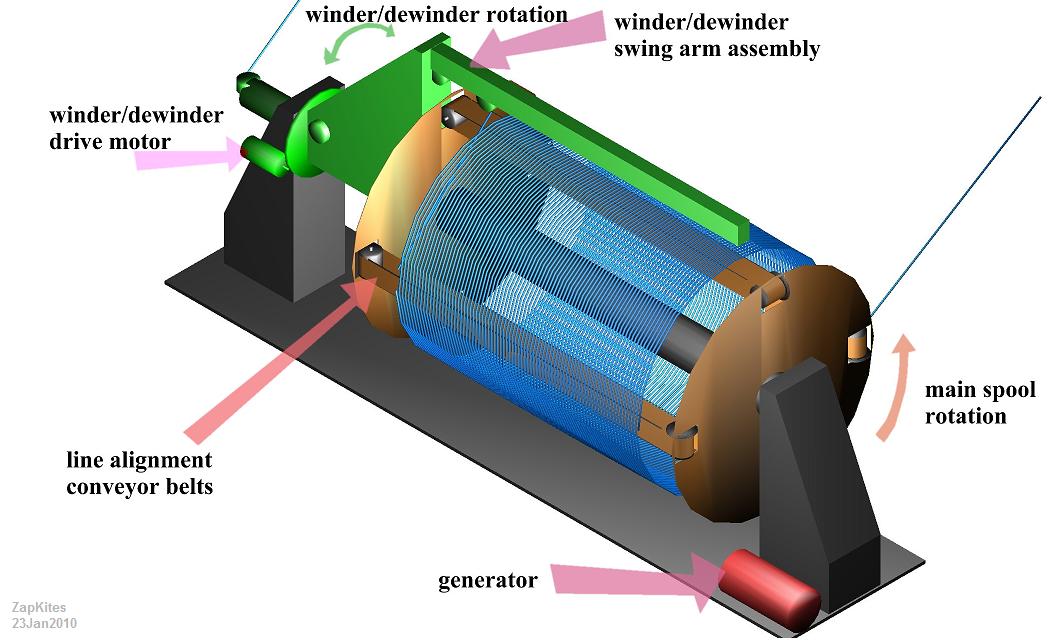

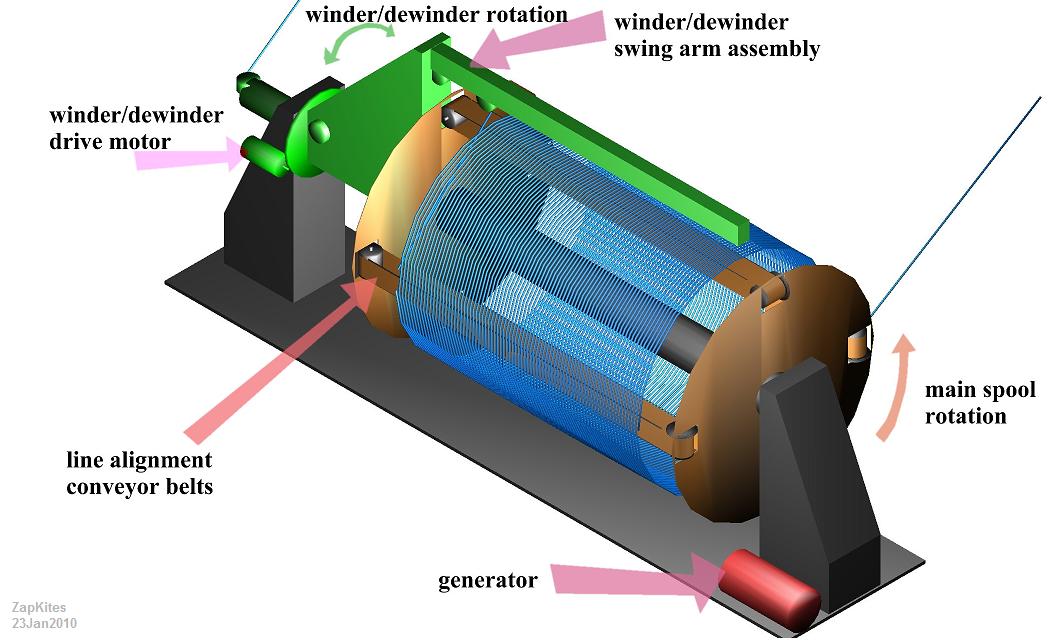

As the main spool (gold elements) rotates, the conveyor belts, which are

geared to the main shaft, travel about 1/2 inch (the line diameter) to

keep the spooled line centered and cancel out the tendency for it to wind

off the ends because of the spiral winding and unwinding.

To pay out line (in blue), the winder/dewinder swing arm assembly (green

elements) rotates counter clockwise (from pictured view). Reverse to take

up line. Line in routed through a hollow shaft with outer roller support

bearings and line will require swivel bearings at 20 foot intervals to

avoid twisting when pay out and take in activation.

Generator (in red) is linked by roller chain to main spool assembly. A

spool diameter of 10 feet and a length of 20 feet should store over 12,000

feet of 1/2 inch line (actually not round, just points on the conveyor

belts. Four belts are pictured but six or eight would be better). This

should give the system the capability to reach several thousand feet of

altitude.

***********************************************************************

Ruff CAD files available (missing some structural support details)

-brooks

PS: This is not the same device I have been mentioning in the past. That

one will be a patented tool available to measure and test all types of

energy systems.

DISCUSSION INVITED:

Notes@EnergyKiteSystems.net

Please copy URL for us when you send a note for this page.

This design is intended to be operational

while winding or unwinding and at any altitude. Depending on the speed of

the wind driven rotation, the unwinding operation may require some braking

of the main spool so that the swing arm can keep up; i.e., if both are

rotating in the same direction at the same speed no line would actually be

payed out.

This design also makes it possible to operate at any altitude. Note that

the blue "line" in the lower right hand side of the picture is the pulling

element; and the take-up side (blue line at far left) is routed through a

hollow shaft on the left side and through a series of pulleys out to the

"swing arm assembly" and back to the "main spool". The "swing arm

assembly" has a pulley mounted on a track that is servo or gear driven so

that as the swing arm (green element) winds or unwinds it keeps the line

properly placed so as to avoid overlapping or leaving gaps much as a

fishing reel does.

Another item with this design I forgot to mention is

that the actual wind-harvesting element loop will need to be connected via

pulley to this endless loop element which is probably a good thing to do

anyway as winds at different altitudes acting on a system that runs the

full length would be much harder to control. This device is meant only to

transfer the mechanical energy to the ground.

-brooks

I will add some of the detail views soon to show how each part functions.

-brooks

Sorry to Brooks for not posting this to JoeF's string

variloop thread earlier, but this is a topic i have worked for several

years now. The finding is that string variloops are a practical AWE power

transmission option.

All you need is a fixed spool that the loop is wound onto over the top of

the spool. As the loop is launched the take-up side of the loop is

passively unwound off the spool. The turbine capstan or bull-wheel is

allowed to roll out the slack return side of the loop as it grows. Once

the loop is fully extended & unwound the turbine then pulls the loop

powering the groundgen capstan or bull-wheel. To retract the process

reverses but the slack side of the loop is now taken up until the loop is

fully wound & landed. Interestingly the loop reverses direction each

session. A detail is that the loop is reverse threaded on the capstans or

bull-wheels each session. One could design to reverse the turbine to

rewind.

A string loop requires a splice or connector fitting. To add to or hotswap

a loop merely requires adding sections by connecting in. To work on a

moving loop is not that hard, may industrial conveyor systems have

sidetrack capabilities, think of train yard operations as a mega example.

This is how KiteLab's successful KiteMotor 1 variloop is manually handled

& automation seems practical. There are many possible variations in

handling variloops & Brooks approach is also workable. Ideas involving

many always-engaged pulleys do stink, but Dan Parker's idea of using terrain

suspension to hide long side-pulled sections is cool. A single pair of

added split-pulleys suffices & any number of such pulleys can be

completely disengaged for zero added friction during power generation.

~coopip

30Jan2010

M1021 [At sites where deep holes are built

to allow water drops, Bob Stuart suggested that few-pulley arrangement

could use the long hole for holding adjustable working endless loop for

tethering an AWECS sky turbine; this has low land footprint and might be

akin to Dan Parker's alternative scheme.]

string variloop

Two general considerations:

1. loop not-working while let out or hauled in.

2. loop works during variation of let-out skied portion.

[2. loop powers during variation]

See discussions:

M945

M1021

jpf

"This is a very secondary requirement with

complexity & capital cost penalty-

2. loop powers during variation

Hidden are differences between reel-in & reel-out states. My

recommendation is focus on essential function (for now). A cool trick,

however, is to use the turbine to winch itself down, which happened

spontaneously one time when a wrong splice knot hung in a fairlead."

ds

30jan2010

But the challenge is very distinct for 1.

and 2. operations. Perhaps for 2.

someone will find an efficient solution; such would allow working loop

during skied-loop extending and shortening.

jpf 30jan2010

Sorry to DaveS for me not explaining my reasoning more

clearly. I see much advantage to having the loop to be variable length,

as with any AWE system: the goal is to find the wind energy and harvest

it. The best wind energy not always in the same place all the time. I have

several different designs scratched out involving connectible segments,

but for simplicity of automated unmanned operation (MY requirement

for AWE to reach a significant level of operation) the winder arm

was my best bet and easiest to CAD up.

-brooks

30jan2010

...stay tuned

|