Free Rotor

I WONDER IF THIS Colin Jack is also COLIN

BRUCE. Colin Bruce JACK. Yes.

Not sure yet what to do with the "Humphry" (without "e" that is shown in the

1992 patent. Yes.

http://emits.esa.int/emits/owa/loadfiles.showfile?p_file=17933%2FEntityDescription.doc

Oxford Mathematical Designs (since 1980s)

Oxford Mathematical Designs Ltd. VAT

number 434 5601

Surface-to-air refueling study done for the UK’s Ministry Of Defence.

Also a science book author under pen name Colin Bruce and software author.

Inventor.

COLIN BRUCE JACK

(preferred naming)

Degree in Mathematical Physics, Sussex University in 1978.

Book writing and research. Three books on mathematics and physics.

One is on quantum physics, published by the US National Academy of

Science’s Joseph Henry Press.

"I am the inventor of several

potentially disruptive engineering concepts, including a type of wind turbine

called the Free Rotor which was offered a development grant by the UK’s

Energy Technology Support Unit

ETSU,

a computer control device called the Baton which anticipated the Nintendo

Wii

by over a decade, and several space propulsion concepts. I have done research

for the European Space Agency on a space propulsion concept I invented in the

1980s, the solar kite. "

PUBLICATIONS: PAPERS & ARTICLES

Solar Sails And Kites (article) Spaceflight, November 1994, Vol. 36 No. 11,

p382-384

The EPR Paradox (article) Physics World, April 1995, Vol. 8 No 4, p39-42

(subsequently adapted for a BBC World Service piece)

A Kinetic Tether System For Launching Payloads (paper, with C S Welch)

IAF-95-V.4.06 delivered at 46th International Astronautical Congress, contact

IAF for reprints

Solar Kites: Small Solar Sails With No Moving Parts (paper, with C S Welch)

IAF-96-S.4.03 delivered at 47th International Astronautical Congress

reprinted in Acta Astronautica, Jan/Apr 1997, Vol. 40 Issue 2-8, p137-142

Spacefarer Solar Kites for Solar System Exploration (with R Wall and C S

Welch)

delivered at 55th International Astronautical Congress, reprinted in

JBIS, May/June 2005, Vol 58 No. 5/6, p155-166

PUBLICATIONS: BOOKS (under pen name

Colin Bruce)

The Einstein Paradox

Originally published in the USA by Addison Wesley in 1997, subsequently

translated into over a dozen languages worldwide.

Conned Again, Watson: Cautionary Tales Of Logic, Math & Probability

Originally published in the USA by Perseus Books in 2001, subsequently

translated into over a dozen languages worldwide.

Schrödinger’s Rabbits: The Many Worlds Of Quantum

Originally published by the National Academy of Sciences’ Joseph Henry Press

in 2004; foreign editions include French, Italian, Chinese (complex),

Japanese.

=====================

Search terms: Colin Jack, Colin Bruce, Colin

Humphry, Colin Humphrey, Free Rotor, 1992020917, autogyro,

WO/1992020917 Free Rotor by JACK, Colin, Humphry, Bruce (one man).

Colin Jack. Colin Bruce.

Multi-rotors are treated.

Faired tethers are recognized. 1992.

Free Rotor

http://tinyurl.com/ColinBruceFREErotor

(WO/1992/020917) FREE ROTOR

by C JACK - 1992

Applicant: JACK, Colin, Humphry, Bruce [GB/GB]; (GB).

... Abstract: A free rotor is a structure which rotates in its entirety,

extracting kinetic energy ...

www.wipo.org/pctdb/en/wo.jsp?wo=1992020917

for original patent

document with images in PDF format From that page, click "Documents"

and then on next served page choose "Download" and choose the

PDF version.

(WO/1992/020917) FREE ROTOR

Pub. No.: WO/1992/020917 International Application No.: PCT/GB1992/000904

Publication Date: 26.11.1992 International Filing Date: 18.05.1992

Chapter 2 Demand Filed: 18.12.1992

IPC: F03B 17/06 (2006.01), F03D 11/04 (2006.01)

Applicant: JACK, Colin, Humphry, Bruce [GB/GB]; (GB).

Inventor: JACK, Colin, Humphry, Bruce; (GB).

Priority Data: 9110791.2 18.05.1991 GB

9111437.1 28.05.1991 GB

9118385.5 28.08.1991 GB

Title: FREE ROTOR

Abstract: A free rotor is a structure which rotates in its entirety,

extracting kinetic energy from a flow in which it is immersed in such a way

that there is no net torque force on it. It is connected via a

counter-rotating joint (U) to a mooring tether (V). The structure is tilted

so that the drag force on the rotor is directed upward of the horizontal,

providing a lift force which prevents the tension in the tether dragging the

structure downward and may also support its weight against gravity.

Electrical energy may be generated by means of secondary propellors (L, M, N)

mounted on the structure at points outward from the centre and forced through

the surrounding medium at high speed by its rotation. The primary

implementation envisaged is an airborne wind generator.

=========================OCR TEXT has errors compared

to the

PDF format, which

see.

Claims:

WO 1992020917 19921126

CLAIMS

1. A structure rotates as a rigid unit, in so doing extracting momentum and

kinetic energy from a flow of air or water in which it is immersed, without

any net torque force being exerted on it by the said flow; its only external

connexion is to a tether which transmits no torque force and which joins a

point on the axis of rotation to a fixed anchorage point below and up-flow of

it; the reaction force on the rotor is arranged to be inclined with respect

to the flow direction, providing a vertical force component which prevents

the tension in the tether dragging the structure downward and may also

provide an additional net lift force.

2. A structure as claimed in claim 1, further characterized in that tensile

members (Fig 1: 0,P,Q) from the rotor blades (Fig 1: I,J,K) to the central

axis transmit the induced loads on the rotor blades efficiently to the

central axis.

3. A structure as claimed in claim 1, further characterized in that at the

rotating joint where the rotating portion of the structure connects to the

non-rotating mooring tether there is provided a joint with a powered motor

(Fig 1: U) which counter-rotates the joint so as to prevent any part of the

mooring tether becoming twisted.

4. A structure as claimed in claim 1, further characterized in that it is

airborne and driven by the wind.

5. A structure as claimed in claim 4, further characterized in that

electrical power is generated by means of secondary rotors placed at points

on the structure outward from the axis of rotation and driven* through the

surrounding air at high speed by the structure's rotation.

6. A structure as claimed in claim 5, further characterized in that the

secondary rotors are of a type whose axis is normal to the incident airflow,

and which are arranged so their axes of rotation are parallel to that of the

main structure (Fig 2c) .

7. A structure as claimed in claim 5, further characterized in that the

secondary rotors are of a type whose axis is parallel to the incident

airflow.

8. A structure as claimed in claim 5, further characterized in that the pitch

of the main rotor blades can be varied so that the structure turns at a

substantially constant rate in all wind speeds, so enabling fixed pitch

secondary rotors to be driven at a constant speed.

9. A structure as claimed in claim 4, further characterized in that the

structure constitutes a self-levitating autogyro; when the wind drops the

structure is forced to continue rotating and flies as a powered helicopter.

10. A structure as claimed in claim 4, further characterized in that a

central lighter-than-air balloon lifts the structure against gravity.

11. A structure as claimed in claim 10, further characterized in that the

central balloon is substantially spherical.

12. A structure as claimed in claim 11, further characterized in that the

airflow over the central balloon is made turbulent so as to decrease the dreg

on it.

13. A structure as claimed in claim 4, further characterized in that the

device can be controlled in orientation and/or in altitude by altering the

pitch of the rotor blades individually.

14. A structure as claimed in claim 4, further characterized in that the

rotor blades are of biplane form (Fig 2d) .

15. A structure as claimed in claim 4, further characterized in that it

diminishes or deflects the wind for the purpose of weather or climate

control.

16. A structure as claimed in claim 1, further characterized in that it is

immersed in water and driven by a current of water.

17. A structure as claimed in claim 16, further characterized in that

electrical power is generated by means of secondary rotors placed at points

on the structure outward from the axis of rotation and driven through the

surrounding water at high speed by the structure's rotation.

18. A structure as claimed in claim 16, further characterized in that it

diminishes or deflects an ocean current for the purpose of weather or climate

control.

=======================================

OCR text

Description:

WO 1992020917 19921126

FRE E ROTOR DESCRIFΠON

Wind generators are a clean source of energy. However existing designs are

inherently poor in several respects. Power is generated in the form of a very

large torque force acting on a large propellor (or other rotor) turning at

low rpm. Massive bearings and gears are required to hold the rotor in place

and convert its motion to power. Heavy structural demands are made on both

the rotor blades and the support tower. Capital and maintenance costs are

therefore high.

According to the present invention is provided a wind generator which is

lighter, cheaper and requires less maintenance than existing designs. The

essential feature of the design is that a rotating structure (which may take

the form of a propellor similar to that of a conventional horizontal-axis

wind turbine, or another type of rotor) extracts energy from the wind without

the need to exert any torque or bending force on any central support. The

device may be airborne and connected to the ground only by a tethering cable.

The rotor is arranged (by tilting its axis) so that the drag force created on

it as a result of its operation is tilted upward from the horizontal,

opposing the tension in the mooring cable, and if desired also providing a

net lift force which helps support the structure against gravity.

Electricity may be generated using small rotors attached to outer points of

the main rotating structure and driven at high speed by its rotation. The

secondary rotors can be conventional propellors; or machines normally used as

vertical-axis turbines such as Cycloturbines or Savon is Rotors or Darrieus

turbines. In this case the axis of rotation of the secondaries and their

attached generators can be arranged parallel to the axis of rotation of the

main rotor, eliminating gyroscopic torque forces.

As well as generating electricity, the devices can be used for

weather/climate control. Whereas ground based wind generators within the

boundary friction layer have little net effect on the wind, airborne

generators slow the wind in which they are placed. Tilted airborne generators

induce vertical air movement, sucking air (typically moving faster and at a

lower temperature) downward from higher altitudes. By choosing which devices

to operate, and steering those devices which are operating in altitude and

veering them to left or right with respect to the incident wind, an extended

aerial wind farm can be used to exert significant control over the weather.

The temperature of an area can be controlled by steering and/or diminishing

hot or cold winds selectively; and the rainfall by steering and/or

diminishing moist and dry winds. Smog control can be performed by forcing

clean air from higher altitude down to mix with relatively static air at

ground level. Amplification effects (such as the 'butterfly effect') might

permit significant climate control even with small numbers of generators.

Note that devices deployed for climate control need not necessarily be

equipped with secondary propellors and generators for electricity

manufacture, and can therefore be cheaper.

SUBSTITUTE SHEET

A similar design to the above, but immersed in water rather than air, can

extract energy from an ocean current or tidal flow, generating electricity.

Water immersed devices can also perform climate control, in particular by

slowing and/or diverting hot or cold ocean currents, and promoting mixing of

ocean waters from different depths. A line of the devices, placed for example

across the mouth of an estuary, can constitute a 'virtual barrage' generating

a significant head tf water on the up-flow side. ,

PRIOR ART

I am aware of two previous types of zero-torque wind generator design. One

well known design uses hollow exhausting blades through which a current of

air is driven try a combination of centrifugal and Venturi forces. A second

design using secondary rotor-tip propellors is disclosed in German patent

application DE 3322589 Al .

There are many patents for airborne wind generators, most commonly for

designs similar to ground based devices but lofted by moored airship or kite.

An airship-based rotating structure design is disclosed in US Patent

4,491,739; and a similar one in US Patent 4,450,364. The most critical

distinction between the present invention and the above is that in the

present invention the rotor structure is designed to be tilted so that the

reaction force generated when the machine is operating, which is parallel to

the axis of rotation, is upwards of the horizontal and acts in opposition to

the tension in the slanting tether cable. In consequence, the lift which must

be provided by the balloon is either reduced by a factor of several or

eliminated, as in toe different examples below. The result is a practicable

generator which is relatively inexpensive and can survive high winds.

I am also aware of US 3,987,987 which discloses various airborne wind

generators based on tethered aircraft, autogyros and kites.

NOTE

The following acronyms are used in the subsequent examples:

BEAN = Bearingless End-braked Autogyro Node

STALK = Stack To Altitude LinKage

In all Figures, arrows labelled W denote wind direction unlabelled arrows

indicate direction of movement.

Note .bat throughout this patent, where reference is made to a rotor acting

like an autogyro, this refers to the fact that incident wind force causes the

rotor to spin while also giving rise to a force acting approximately along

die axis of spin. Of course the rotor may be deployed at any angle to the

wind, ranging from axis of rotation approximately at rigid: angles to wind

direction to axis of rotation approximately parallel to wind direction. In

the former case, net airflow through the rotor resolved in the axial

direction may be in a direction opposite to that of the incident wind vector

resolved in the axial direction. In the latter case, net airflow through the

rotor resolved in the axial direction may be in the same direction as the

incident wind vector resolved in the axial direction. Reference to autogyro-like

behaviour denotes a simile rather than an exact correspondence. When the axis

of rotation is almost parallel to the wind vector, die rotor acts more like

a conventional propellor than like an autogyro blade.

Note that whereas in some instances 'STALK' refers to a stack of primary

rotors, in others it denotes the system of tethers used to anchor a single

rotor to the ground.

EXAMPLE 1

This example is illustrated with respect to Figure la showing the device in

elevation and Figure lb showing the rotor in plan (in Figure la only two of

the three rotor arms are visible) in which:

The central spherical helium balloon A provides static lift which supports

the device against gravity. The balloon A is connected by a plurality of

tensile members W (only some of which are shown) to a surrounding rigid

triangle of members C, D, E, at the corners of which are attached three rotor

blades I, J, K, via joints F, G, H which hold them rigid with respect to the

central triangle but permit them to be rotated about their axes so as to vary

the pitch of each blade.

The device is attached to the mooring cable V via a rotating joint at the

connecting structure U which allows the entire structure to rotate as a unit.

The rotating joint may be actively counter-rotated by means of a small motor

to prevent the mooring cable V beoming twisted as the device spins.

Tensile members R, S, T connect the 1'nlring structure U to the central

support triangle. Additional tensile members O, P, Q (which may have a

streamlined airfoil-like cross-section, rather than circular, so as to

minimize the drag on them induced by the structure's rotation and thus minimi

TO the energy so wasted) connect directly to the rotor arms I, J, K. They

become taut when the device is operating, so greatly reducing the bending

forces which the rotor arms must be capable of withstanding, and thus their

structural weight.

The energy of rotation imparted to tiie structure by the wind is harvested by

means of small secondary propellors L, M, N connected to high-rpm

aircraft-type generators. These propellors are driven through the air at many

times the incident wind speed due to the structure's rotation. Because the

energy in an airflow is proportional to the cube of the velocity, and the

main rotor tips may be driven at up to — 12 times the incident wind speed,

relatively small secondary propellors can harvest all the energy generated.

The pitch of the primary blades is varied with wind speed to keep the rate of

rotation constant: thus the secondary propellors may be fixed in pitch yet

drive generators at constant r.p.m.

The device may be deployed at almost any location. A particularly

advantageous site is at sea over the continental shelf. The tether V then

connects to a buoy (not shown) and mooring line to the sea bed.

In a flat calm, the device hangs vertically with most of the tether V

floating on the water and the structure U a short distance above the surface.

The static lift of the balloon A is just sufficient to support the weight of

SUBSTITUTE SHEET

the structure. As the wind gets up, the structure tilts slightly and starts

to autorotate, so producing an autogyro-style lift force. (The device may

also be force-started. An electric generator is also a motor, so power can be

fed to tiie secondary propellors to initiate rotation of die device, so

providing manoeuvering control iτ-Vrι-rιing βverι m a ffø calm.) The -n~~-'tt-r'*

and orientation of the lift force may be controlled by altering the pitch of

the individual rotor blades as the device turns. In this way the mooring line

is lifted . from die water and pulled taut, and tiie device steered to the

operating position shown in Figure la. Cyclic pitch control of the rotor

blades can be used to alter tiie inclination of the axis of rotation, forcing

it a few degrees up or down from the inclination of the mooring line, and so

controlling -be altitude of the device. In particular, in very high winds, a

substantial lift force can be generated to prevent ti e drag on the central

balloon forcing the structure down into the sea.

The drag on the central balloon may be considerably reduced (from Cd=0.5 to

Cd=0.1) Toy malting the flow over its surface turbulent. Its rotation alone

may induce the necessary turbulence, or it may be assisted by roughening tiie

surface of the balloon, and/or using a balloon which is polygonal (e.g. a la

Buckminster Fuller geodesic with stiff cables or belts attached internally to

the balloon's surface, whose intersection points may also provide convenient

anchorages for tiie guy wires W) rather than perfectly spherical; and or by

attaching 'spoiler' devices to the structure; or by other means. Thus the

device can survive the most severe storms and wind gusts in situ while

continuing to operate.

The device may be built and serviced at a land-based facility, e.g. in a

dockside hangar. It may be towed to its mooring when already airborne,

allowed to autorotate as it does so, by a small boat, and recovered in the

same way.

The device is controlled by a simple autopilot (e.g. a microprocessor).

Sensing devices may include accelerometers, inclinometers, rotation sensors,

wind sensors, force sensors, altitude sensors, etc. Control may be exerted

solely by varying the pitch of the primary rotor blades or in other ways,

e.g. with aerodynamic control surfaces; varying the length of combinations of

any of the wires O, P, Q, R, S, T, W; pumpimg ballast water up and down a

pipe within the tether; etc.

The cables O, P, Q attach to the rotor arms I, J, K at tiie point on the

chord corresponding to the centre of lift, via hinges which may be recessed

into the wing surface. There may be means provided to tighten and slacken, or

jettison altogether, the cables O, P, Q and/or the cables R, S, T during

deployment and/or recovery operations, to ensure the cables O, P, Q do not

exert unwanted bending forces on the rotor arms at these times.

Lifting gas will leak from the balloon over time. This may be compensated by

including water ballast which is progressively jettisoned; or an insulated

flask of hydrogen or helium which evaporates in a controlled way to replenish

tiie lifting gas; or providing a pipe or pipes within tiie mooring tether

which can be used for pumping lifting gas and/or water ballast up to the

structure from below.

The power generated is transmitted to land down the tether (ohmic heating of

the tether cable as a side-effect will help prevent icing) and then via

seabed cable. Power will typically be generated at high frequency and

relatively low voltage; boosted to higher voltage by a transformer on the

seabed, or floating immersed attached to the mooring line for easier

recovery; transmitted to land; then transformed or inverted to reduce the

frequency to mains supply. Other combinations are of course possible: for

example the high frequency power may be inverted to DC, transmitted

efficiently to land and then across a DC land grid, and restored to AC near

the point of consumption.

Note that many detailed arrangements of the wires labelled O, P, Q, R, S, T,

W are possible, including different numbers of attachment points and choices

of attachment points to the central balloon, support triangle, and rotor

arms. Winches or hydraulic pistons may permit the lengths and tensions of any

of these wires to be varied. Additional wires may be employed, for example

connecting the rotor arms one to another, or to the central balloon, to make

the structure stronger and/or more rigid. Internal wires within the central

balloon may pull it into a puckered shape so as to make the airflow over it

more turbulent.

In a variant of the design, the rotor arms may be hinged so that they hang

vertically when the device is static, and are deployed by centrifugal force

as the device is started by forcing rotation using the secondary propellors.

In a related variant which is a purely tensile structure, the rotor inner

ends may be connected directly to the central balloon by tensile cables

without the need for a central support triangle: when the device is not

operating the blades hang vertically beneath the balloon. To avoid tangling

during deployment and recovery, tiie guy wires may be capable of being wound

in and out in synchrony with each attached to an individual electric winch at

its endpoint(s). Alternatively the guy wires may initially be held to minimum

length by ties which break open as the structure spins up, and all but the

outer guys may be jettisoned as the structure spins down for recovery.

In another variant of the design, the tensile cables R, S, T may be replaced

by rigid structural members forming a rigid tetrahedron whose vertices are F,

G, H, U.

In another variant the central rigid triangle C, D, £ may be inside rather

than outside the central balloon.

Of course there may be a greater number of rotor blades than three.

Two-bladed designs are also possible, but have poorer orientation-holding

stability against yaw and pitch forces.

The central triangle may be another structure, e.g. one having more sides

and/or members extending in the structure's axial direction rather than being

confined in a plane. Shrouds may be mounted on structural members to minimize

drag on them and hence wasted energy.

Gyroscopic forces on the propellors and their attached generators as their

axis of rotation is forced to change

SUBSTITUTE SHEET

continually by the main structure's rotation may constitute a problem. The

propellor axles may have mount points both forward and aft of the propellors

to help counter this. The propellors may as shown in Figure 2a be connected

to gears A which drive generator shafts in tiie opposite direction to ti e

propellors so minimizing the net angular momentum and hence the gyro torque

force the system exertson its mount.

Secondary propellors may be mormte m counter-rotating pairs. Or a plurality

of small propellors may be used in place of each secondary propellor. Due to

their higher rotation speed, these can be mounted each on the same axle as

its generator, with no gear transmission. Half tiie small propellors in each

assembly rotate clockwise, the rest anticlockwise.

Propellors (Fig 2b) whose axis is parallel to in incident airflow may be

attached to gears A which drive generator shafts B at right angles, thus the

attached generators C may be aligned with their spin axis parallel to the

spin of the main structure.

If the secondary propellors are mounted near tiie tips of tiie primary rotor

blades and their direction of rotation is correctly chosen, they may interact

beneficially with the airflow over the primary blades by cutting down the

airspill over the ends of tiie primary blades and minimizing the tip vortices

thus created.

Conventional propellors may be mounted on the rotor blades with their axes of

rotation parallel to the structure's spin axis if deflector plates around

tiie propellors deflect the surrounding airflow through them.

In another variant of tiie design, tiie central balloon is omitted, and the

autogyro-like lift provided by the rotaϋon of the rotor keeps its weight

airborne. When the wind drops, power supplied from the land drives the

secondary propellors to force the structure to continue rotating so it

continues to fly but in a helicopter-like manner.

h another variant of the design the central rigid triangle is omitted and the

rotor blades attach directly to the central balloon which is either inflated

to sufficiently high pressure to itself act as a compressive structural

member and or reinforced with internal compressive members. The balloon may

take an axially elongated form (more like an airship) extending as far as the

joint U, and the wires O, P, Q may attach to the airship hull. Additional

wires from the rotor arms to the aft end of the hull may help prevent them

bending downward when the device is not operating and its axis is vertical.

Cross-wires from points on the rotor arms to points on the circumference of

the airship hull may help secure the rotor arms against sideways movement.

In another variant of the design the rotor blades have biplane form, thus

improving their ability to withstand bending forces at the expense of

aerodynamic efficiency. This may make it possible to eliminate the tensile

members O, P, Q.

In another variant of the design the central balloon is not spherical but

takes a more conventional airship-like shape whose axis of symmetry is the

axis of rotation of the structure.

The main part of tiie mooring cable V does not rotate and so may be given a

streamlined airfoil-like profile, said housing enclosing the various

structural cables, electric cables, control signal cables, pipes, etc. .

In another variant of the design the central balloon may be a rigid-hulled

structure. For example panels of corrugated fibre-reinforced plastic are

strong and also help seed surface turbulence as the structure rotates.

Variations on the design listed above and given also in the examples below

may be combined with each other and with other variations in many ways which

should be obvious.

EXAMPLE 2

A water-immersed variant of the device is shown in Figure 2e. It can have

approximately neutral buoyancy and of course requires no central lifting

balloon. The blades A may be made, for exanφle, of fibre-reinforced wood; or

hollow steel filled with a light oil fraction or ice or compressed air.

Alternatively they may be made of fabric like a paraglider.

There is no need for a central rigid structure and the inner ends of the

individual rotor blades A can be connected to one another by tensile wires B.

The structure can be equipped with secondary rotors for electricity

generation as in Example 1, or be used for weather/climate control purposes

only.

EXAMPLE 3

The key element of the device is a large rotor blade (the 'BEAN') which is

deployed at an angle to the incident wind as shown in Figure 3, in which a

twin-bladed main rotor A is seen from the side at the moment during its

rotation when it lies in the vertical plane. The central tether K is the axis

of rotation of the whole system, comprising the rotor and all tethers

attached to it.

The wind force on the rotor generates both a torque force tending to

accelerate its spin, and a lift force directed along the axis of the rotor,

as in tiie hybrid type of aircraft called an autogyro.

To counter the torque force generated, and so harvest the energy, smaller

secondary propellors are situated at the ends of the blade, coupled to

electric generators. In Figure 3, rotation of the primary blade A drives the

propellors B so generating electricity.

SUBSTITUTE SHEET

For effcient operation, tiie primary A is allowed to rotate with a tip speed

up to ~7 times greater than the windspeed. The secondary propellors B should

have a combined capture area about 1/200 that of the primary, so they each

have a diameter about 1/20 that of the primary.

Variations in wind speed can be coped with by varying .the pitch and/or tiie

rotation speed of the secondaries B. So the primary A can comprise a simple

rigid structure, as distinct from a variable-pitch propellor whose geometry

can be altered.

Altiiough tiie large primary A rotates a low r.p.m., the secondaries B spin

at high r.p.m. (Tip speed of B can be up to ~ 50 times wind speed, and will

be limited only by tiie speed of sound in most circumstances.) So the

propellors B provide low torque force at high r.p.m., and can drive efficient

electric generators with either no intermediate gearing or a single stage of

gearing. Propellors B are of conventional size, and can function for ~ 5,000

hours without maintenance. The generators to which they are attached can

provide high power to weight ratios, (up to several kw/kg) since high

disspiative losses are acceptable and power may be generated at high

frequency (e.g.250 Hz), with subsequent transformation to mains frequency on

the ground.

The primary blade is tethered to the node C below not just at the centre D,

but at several points E, F along each wing of tiie blade, thus distributing

tiie strctural load evenly. Some of tiie tethers L run to points E near the

leading edge of each wing, and some to points F further aft, so that the

orientation of the propellor is fixed by its postion with respect to tiie

anchoring node C. The tethers E, F may have an aerodynamically shaped

cross-section so as to minimize the drag force on them as they rotate. The

primary blade may be thicker towards tiie central axis, where drag is less

important, to prevent it buckling under longitudinal compressive force and

help it resist bending.

The tethers L may be made ofa material such as dural which has useful

conducting as well as structural properties. Polyphase current can be

transmitted to the ground, each tether carrying one phase. The tethers need

insulation only near their endpoints.

The structure is capable of being 'steered', by varying the drag force on the

secondaries B in synchronization with tiie rotation of tiie primary A. Thus a

radial force in any desired direction may be generated. The speed of rotation

of the structure is controlled by varying tiie amount of drag on the

secondaries B.

EXAMPLE 4

A more sophisticated form of the structure is shown in Figures 3a (viewed

along main axis), 3b (viewed in plane of rotation), and 3c (detail of rudder

structure, viewed in elevation).

The secondary propellors B (4 in all) are placed away from the airflow over

the rotor. The structures on which

they are mounted G are winglets equipped with rudders H as shown in Figure

3c, each resembling the tailplane of an aircraft. The tensile wires I prevent

centrifugal force on the generators from bending the winglets outward. By

adjusting the rudders H as the structure rotates, a large radial force can be

generated in any direction.

A further control mechanism is provided by ailerons K set in the trailing

edge of the main rotor. These can be used to vary the angle of deflection of

the airflow over each wing of the rotor. Normally they will be levelled as a

rotor blade travels against the wind, and inclined as it travels with the

wind. This ensures:

(a) lift force on each wing remains constant as the structure rotates,

preventing a tendency to slew.

(b) As shown in Figure 4, the reaction force Y on the wings is consistently

upward of the vector X normal to the rotor, thus helping to counter the

weight of the rotor and the drag on the tethering lines C.

Yet further control may be provided by installing control surfaces of various

types (flaps, droops, spoilers etc.) anywhere on the structure, and or by

swivelling the propellor/generator assemblies to provide vectored thrust

The structure is threaded by a major cable K. It is attached along its span

to tethering lines L meeting at a node C below it, and additional tethering

lines M meeting at a node N above it Thus whether the net force on tiie

structure is downward (e.g. when there is no wind, when the blade is not

rotating, or during deployment) or upward (e.g. during normal operation) it

is supported uniformly along its length. The lengths of the wires L and M are

so chosen that at any given time one set is taut and the other slack (all

cannot be taut simultaneously).

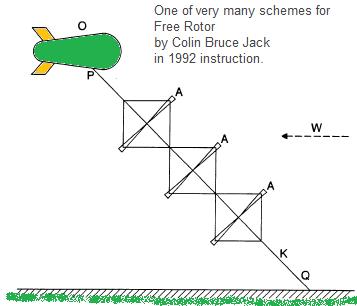

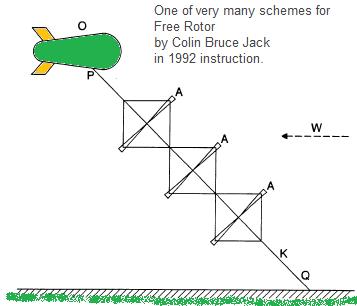

EXAMPLE 5

BEAN elements may be assembled into a 'STALK' composed of any number of BEANs

(including one) as illustrated in Figure 5. The upper end of the STALK may be

supported by a tethered balloon O. (This may have a streamlined airship-like

shape as shown to nunimize the wind drag on it). The central cable K may be

made of a material having very high strength-to-weight ratio such as Kevlar.

The secondary cables L, M may be made of conducting material (e.g. Dural) as

in Example 4.

The whole structure is constrained to rotate as a unit (e.g. by varying the

drag force on the sets of secondary propellors B in an appropriate way) so

that the central cable does not become twisted. The only rotating joints

required are at tiie top of the structure P, where it attaches to the

airship, and the base Q, where it attaches to the ground. The rotation at

these points may be forced (e.g. using small electric motors) to ensure no

twisting occurs at these points.

While in the air, the structure can be actively controlled. The force on any

rotor blade may be varied by the methods described in Examples 3 and 4.

Active control can achieve the following benefits among others:

(a) The STALK can be forced to a specific, optimal, elevation angle.

(b) Catenary hanging of the STALK may be m __nized, to keep it straight.

SUBSTITUTE SHEET

(c) The STALK can be forced to a given angle with respect to the incident

wind direction.

(d) Large scale oscillations in the STALK can be damped or prevented from

starting.

(e) The STALK may be bent along its length to allow for variations in wind

speed and direction with altitude.

Note that by using tiie secondary propellors B, the structure may also be

controlled when it is stationary-. The secondaries can be made to induce drag

(simultaneously generating a small amount of power, if desired), or driven

(e.g. by electric power supplied from the ground) to produce thrust This is

relevant to the starting and stopping of the rotation of the structure, to

preventing rotation during deployment and recovery, and to providing lift and

guidance forces during deployment and recovery.

Individual rotors may be equipped with tiieir own sensors for monitoring

position, orientation, incident wind, etc.

Note that all cables are in place tiiroughout deployment, so power and

control can be provided from the ground at all stages in deployment and

recovery without interruption. Some fully insulated conducting cables may be

incorporated (of relatively low power-carrying capacity) to allow power to be

supplied without involuntary cross- connexions or earthing occuriαg during

these operations.

The structure is deployed and recovered as follows. Initially the rotors rest

on tiie ground adjacent to one another (or stacked). The cables connecting

them are already fastened in place, but are slack. Consider tiie nodes to be

labelled 1 (the node immediately below the balloon), 2 (the node below tiie

uppermost rotor), 3 (the node below the second uppermost rotor), and so on in

sequence.

The balloon might simply be released, allowing the structure to self-deploy

with each rotor pulling the next into the air as it rises. For more

controlled deploment, however, two sets of winches are used, designated S and

T. Initially winch set S are connected to node 1 and are taut and set T to

node 2 and are slack. The set S are wound out until the balloon has lifted

the first rotor into the air, set T become taut and set S slack. Now set S

are disconnected from node 1 and connected to node 3. Set T are wound out

until the second rotor is in the air and set S are taut; set T are

disconnected and connected to node 4; and so forth.

To recover the STALK the operation is simply reversed. To do this it is

necessary to attach winch cables to nodes which are one rotor height above

the ground: a light crane with an appropriate instrument attached to its jib

may be used to do this. Gas may be released from the balloon as the structure

is hauled in, minimizing tension in the winches.

Note that there is no requirement for any cable which is part of the

permanent structure (either the Dural conductors or the central Kevlar

tether) to be wound on a winch under tension, either during deployment or

recovery.

The STALK may be kept operating even if individual parts fail. For example if

the bearings of a secondary propellor or its attached generator fail, the

pitch of the blades of the stationary propellor may still be altered to

produce the drag force required. If even the pitch control mechanisms fail,

other secondary propellors on the other blade tips of the affected rotor may

be used to control its motion so that it does not spin out of control. _

EXAMPLE 6

This example describes an alternative form of STALK illustrated in Figure 6.

In this form, rotors are cross- connected by wires such as R (rather than

being seperated by nodes) so that the whole structure becomes rigid under

tension. An advantage is that the string can be controlled using just one or

a few rotors (e.g. the topmost one) which are equipped with the control

mechanisms described in Example 4.

EXAMPLE 7

This example lists alternative upper suuports for the stalk. These include:

(a) The supporting balloon may be equipped with small electric motors and/or

rudder and fins, to allow it to manouvre. This may be useful to hold the

STALK at a desired angle, e.g. to optimize performance or prevent it becoming

twisted or entangled with neighbouring STALKs in exceptional weather

conditions such as flat calm or high relative turbulence. A manouverable

balloon may also assist during deployment and recovery, by pulling the upper

end of the STALK to a desired position and holding it there.

(b) The supporting balloon may be a circularly symmetric shape (e.g. a

flattened disk) so that it can rotate freely. This removes the need for an

upper rotating join. Rotation might be assisted by small tangential

propellors, to prevent twisting.

(c) A self-propelled airship. The STALK hangs below the airship, either with

all rotors aboard, or strapped just below the ship, or already deployed as a

string. The airship travels to the point where the STALK is to be moored.

This might be e.g. a buoy or disused oil platform at sea. The STALK is

moored, and power generation starts.

(d) A conventional heUcopter. After deployment and rotation is initiated, the

STALK becomes self-supporting due to the autogyro effect, and the helicopter

can detach and return to base.

(e) The topmost element of the STALK is a heUcopter with electrically driven

blades (power is provided along the STALK). After deployment, the angle of

the blades is altered and the heUcopter becomes an additional

power-generating autogyro.

(f) A disposable balloon which is jettisoned upwards after deployment is

complete.

(g) The rotor or rotors might take themselves take the form of lightweight

structures (rigid or inflatable) filled with a light gas or with hot air

(waste heat from the generators), so that each can support its own weight by

static lift

(h) The secondary propellors B can be swiveUed so as to provide directed

thrust, drive power being suppUed

SUBSTITUTE SHEET

f_om tiie ground. The propellors B can be used to provide lift, so that each

rotor can rise from the ground under its own thrust lift may similarly be

provided by seperate vertical-axis propellors mounted on any rotor, or the

topmost one, e.g. at the centre of the rotor. (0 The primary propellors may

be spun on a ground based turntable or turntables so that they can take off

and/or land using tiieir own lift force. .

(j) Parachutes may be deployed from any rotor, or the topmost one, to assist

in recovery, (k) Jet engines or solid-propellant rockets may lift the rotors.

(D Forced airflow provided by propellors or jet turbines on the ground may be

used to lift the rotors, (m) The rotors may be flown off or landed like a

kite, lifting in the wind without rotating by angling the blades

appropriately. During operation, supplementary lift may be provided by wing

structures attached to the central tether K and/or designing the upper

balloon to have a lifting-body shape. In tiie absence of wind, power suppUed

from tiie ground to the secondary propellors may be used to keep the

structure rotating and hence generate lift

EXAMPLE 8

This example describes alternative sites to which the STALK may be deployed.

In each case, the STALK may be recovered by the same means by which it is

deployed. In each case, each single set of deployment equipment and storage

and servicing faciUties can supply many STALKs to different sites.

(a) The STALK may be attached to a buoy or moored vessel at sea. An undersea

cable to land transmits the power generated. The STALK may reach this site

by:

(1) Being deployed from an appropriately equipped vessel, e.g. an oceangoing

barge, at the site.

(2) Being transported and deployed from an airship as described in Example

7(b).

(3) Being deployed as described in Example 5, from a site which is adjacent

to a seaport After deployment, the anchoring end of the STALK is transferred

to an oceangoing tug, which proceeds to tow the airborne STALK to site. The

tug either moors there for the duration, or transfers the anchoring end of

the STALK to a buoy.

(b) The STALK may be attached to an unmoored sea vessel, either drifting or

proceeding under power. The electricity produced might be used to generate a

storable fuel, such as hydrogen electrolyzed from sea-water. The vessel may

foUow a course so as to maximize the wind energy accessible, e.g. by

remaining under one of the major jetstreams.

(c) The STALK may be attached to a point on land other than than at which it

is initially deployed, either:

(1) Being transported and deployed from an airship as described in Example

7(b).

(2) Being transported from one site adjacent to the sea or a canal to another

(e.g. from a port to a set of coastal or offshore island sites) by oceangoing

tug or similar vessel as described in Example 8(a)(3).

(3) Being transported from the site of original deployment to another site by

being moored to a mobile land vehicle, e.g.:

(a) A heavy tracked vehicle.

(b) A railway vehicle, which might run on more than one set of parallel

tracks. In use, the anchoring end of the STALK might be kept on board the

vehicle (which could be secured to the spot by ties), or transferred to a

separate ground anchorage point The STALK might be deployed to a hill or

mountain top to minimize tether length and/or maximize wind speed past the

rotors.

. EXAMPLE 9

This Exanφle lists alternative forms which the main rotors might take:

(a) Biplane structure.

(b) Triplane, quadriplane, etc., structure.

(c) Inflatable structure.

(d) Tensile structure held deployed by centrifugal force.

(e) Tensile structure held deployed by aerodynamic forces.

(f) Thin-walled structure held rigid by internal pressure.

Note that although the primaries are depicted in the Figures as having two

blades each, both the primary and secondary rotors may have an unrestricted

number of blades. There may be any number of secondary blades (from zero to

several) on each primary blade tip.

As weU as being equipped with flaps (and/or other aerodynamic surfaces) the

geometry of the rotors may be alterable in other ways. For instance rotating

collars at the central join may permit the pitch of the blades to be altered.

The length and or anchorage points of the tethering lines C and E may be

capable of variation (e.g. by winches, hydrauUc pistons, etc.) so as to warp

the rotor, or move one part relative to another, or vary cycUcaUy in such a

way that the plane of rotation of the rotor Ues other than normal to the

central tension cable.

The rotors may be attached to the central cable only at the midpoint (with no

auxiliary supporting lines C, E to other points as shown in Figures 3) if

they are sufficiently strong. For example a biplane rotor could be of this

type. In this circumstance, appropriate moving joints (e.g. a universal

joint) might permit the rotor to turn in a plane other than normal to the

central tension cable. The joints might be motor driven so that the rotor

could be forced to a chosen angle with respect to the central cable.

The blades of the rotor need not necessarily Ue in the same plane, e.g. they

might form a shallow cone. The dihedral angle may be adjustable. For exanφle

once the blades are spinning the central joint may hinge freely so that the

blades adopt an equilibrium angle determined by the ratio of centrifugal

force to axial drag force.

The rotor blades may be deployed only once aloft, e.g. if they are tensile or

inflatable structures.

SUBSTITUTE SHEET

The rotor blades may be capable of extended deployment once the rotor is in

die air and rotating, e.g. by the blades extruding telescoping sections, or

by allowing the central structure to extend so increasing the overall

diameter of the rotor. The lengths of the bracing wires L, M may be

adjustable.

The rotor blades may be de-iced by circulating waste heat from the generators

along them (e.g. in tiie form of hot air) or by electric heating elements.

The directions of rotation of the secondary propellors mounted on a given

rotor may be chosen so as to minimize gyroscopic forces as tiie rotor turns.

Rotors may be mounted on a non-rotating cable by means of a bearing

permitting rotation. Consecutive sections of the main cable may rotate in

different directions or at different speeds if they are joined at a collar or

bearing permitting rotation. In either of these cases, individual rotors may

turn each at an independent speed and in either a clockwise or anticlockwise

direction.

EXAMPLE 10

This Example lists alternative ways in which energy may be generated by the

system once airborne. Note that once tiie system is deployed, it can support

a larger weight than could be held up by the top balloon alone due to the

autogyro lift effect Thus for example a Ughtweight pipe can be filled with

water once the structure is spinning without causing it to descend.

(a) Rotor blades may be lofted into a Jetstream.

(b) The rotor-tip energy harvesting devices may be other than propellors,

e.g. enclosed turbines, turboprops, etc.

(c) Pairs of counter-rotating rotors may generate energy directly from the

torque force between them, without the need for rotor-tip energy harvesting

devices.

(d) The temperature difference between air at low level and air at high

altitude may be used to generate energy, e.g. by using a working fluid which

rises up the structure as a vapour, condenses at the top and flows back to

the base, or theπnoelectrically. The rapidly turning rotors will serve as

efficient heat exchangers.

(e) Water may be pumped up the structure, flow out to the tips of the rotor

blades and be expelled rearwards relative to the direction of turn. The water

may pass through turbines en route so generating energy.

(f) The difference in electric potential between air at high and low

altitudes may generate a current flow. This may be maximized by mati g the

airflow over the rotor blades turbulent; by dissipating water vapour to

increase the conductivity of tiie surrounding air; or by using trailing or

fixed wires, meshes or cages attached to parts of the structure, including on

the rotor blades.

EXAMPLE 11

This Example describes how mechanisms described in this patent may be used

for purposes of weather or climate or

other environment control:

(a) By choosing at what times, places, and altitudes to extract energy from

the wind and thus slow the local airflow. Place of extraction may be selected

by drawing power from a selected subset only of an extended network of STALKs,

or by the STALKS themselves being mobile (e.g. as the ship-mounted variety

described in Example 8(b)). .

(b) By deploying the rotors so as to alter tiie direction of the surrounding

airflow.

(c) By deploying the rotors so as to suck cold air down from high altitude to

low altitude, or lift warm air from low altitude to high altitude, etc. Note

that a 'cascade' or 'staircase' effect can be set up to pass the same air

from one rotor to the next

(d) By deploying the rotors to increase the turbulence of the surrounding

airflow. For example, causing a localised Jetstream to exchange momentum and

material with the surrounding air.

(e) By supplying power from the ground to the rotors, so setting static air

in motion, or accelerating the surrounding air; in particular to trigger a

self-sustaining process, such as allowing an unstable system of cold air over

warm air to right itself.

(f) By pumping water up tiie structure to be sprayed out at altitude.

(g) By dispersing 'seeding' material (encouraging the formation of ice

crystals or water droplets) from the structure.

(h) By dispersing soot particles or other sunUght-absorbing particles from

the structure.

(i) By dispersing any kind of material from the structure.

(j) By deploying the rotors so as to suck polluted air from low altitude to

higher altitude, or suck fresh air down from high altitude to low altitude.

Other structures than the rotors might be deployed from the structure to

assist weather control functions by interacting with the airstream, e.g.

braking parachutes, paragliders, etc.

Note that the 'butterfly effect' can be employed to enable a small initial

alteration to lead to a much larger subsequent change in the weather pattern,

including at points remote from the STALK system(s).

'Weather control' can of course include the dispersal of low-lying smog,

cloud or fog. In particular note the possibility of dispersing smog from

areas such as tiie Los Angeles basin by injecting clean air from higher

altitudes using a BEANSTALK or cascade thereof.

EXAMPLE 12

This exanφle describes in more detail how electric power may be conveyed from

the generating sites on the STALK to the ground.

(a) Tngιιlnt_v* conducting members may be cooled by allowing cold air to pass

along a passage within them. The airflow may be created by passive means,

e.g. using tiie fact that hot air rises; using the dynamic pressure of tiie

wind; using the dynamic pressures created by the turning of the rotors (e.g.

by having air enter and

SUBSTITUTE SHEET

leave from slots or scoops situated on the rotor wings); and/or using the

Venturi or Bernoulli effects. Air may enter and leave such a system at many

points along its height

(b) The transmission voltage may be raised well beyond tiie insulation limits

of individual generators if a chain of generators are connected in series.

Since generators are effectively isolated from the ground as weU as from one

another, a high potential difference between generators, or between a the

generator casing and the earth, does not matter.

(c) Power may be generated at different frequency from that required (e.g. as

DC to minimize the weight of tiie conductors carrying tiie current to the

ground, or at high frequency to minimize the mass of the generators), being

transformed to mains frequency by apparatus on tiie ground.

(d) lightning strikes may be protected against either by arranging for

circuit breakers, isolators etc. situated anywhere on the structure (on tiie

rotors or on the cables) to effectively insert a large thickness of ■nmilating

material between individual rotor blade tips, between separate rotors, and or

between ti e rotors and tiie ground below; or by arranging for all of tiie

conductors to be cross-connected so that all cables which normally transmit

power from the rotors to the ground act as a combined Ughtαing conductor of

high capacity.

EXAMPLE 13

An apparatus identical or very similar to that described in each above

Example may be deployed in water, as distinct from in air, to harvest energy

from the flow of water in tiie form of an ocean current, a tidal flow, or a

river current The structure may be given an overall negative buoyancy,

positive buoyancy, or neutral buoyancy. The anchorage point of the tether may

be to a fixed structure situated on the sea bed below; or to a fixed

structure situated on land above; or to a fixed intermediate point (such as

the peak of a submarine mountain); or to eitiier a mobile structure or a

second rotor system which may be eitiier floating or airborne and is immersed

in a medium flowing at a different speed and/or in a different direction to

the current surrounding tiie rotors.

As a specific example, a STALK of rotors each having a stight positive

buoyancy is tethered to a point on the seabed beneath a permanent ocean

current Such currents have speed — 10 times less than wind speeds: however

sea-water is 1000 times denser than air, so the density of kinetic energy

available per unit area is similar to that for an airborne structure. Current

may be transmitted from the STALK base to land via an urdersea cable. The

salt-water in which the system is immersed may be used as a current conductor

(e.g. for one phase of an alternating current produced).

Of particular importance is the effect such a structure could have on

weather/climate/environment control. Where tiie rotors are in sea water whose

temperature differs from that of its surroundings (e.g. in a warm current

such as tiie Gulf Stream, or due to tiie temperature difference between the

sea surface and the depths) the relative thermal energy in each tonne of

sea-water may be 4 to 5 orders of magnitude greater than ti e kinetic energy.

UTE SHE T

Thus extracting a small amount of kinetic energy can be used to cause major

environmental effects, by slowing or diverting a sea current, or by

transporting water between different depth layers in the ocean. Setting up

turbulence in the current flow may enable ocean silt (carrying plankton

nutrients) to be stirred up from the sea bed and distributed. The melting or

formation of ice and the subsequent flow of the water and/or icebergs

produced may also be controlled. .

EXAMPLE 14

This Example describes in more detail how the STALK described in Example 5

may be deployed and recovered.

The balloon supporting the top of tiie STALK is an an unmanned airship

equipped with electric motors (powered from the ground via the STALK) which

are capable of propelling it in any lateral direction. If the airship has

circular symmetry (e.g. disk shaped) this may be accomplished without

changing orientation. (The motors may also be capable of propelling it in the

vertical direction.)

The airship may use a Ughter than air gas such as hydrogen, helium or

methane, to provide lift; or hot air; or steam; or a combination (to permit

both high lift and controllability). Note that power (e.g. to heat hot air)

may be provided via the STALK; also, via a suitable pipeline on the STALK,

tiquids or gases (water, hydrogen, etc.).

Th~ lift force from the airship may be varied by taking on board or expelling

overboard ballast (e.g. water) anα or by taking on board or expelling

overboard gas (e.g. hydrogen, hot air, steam) and or by condensing steam to

water or vice versa and/or by its motors.

Initially the BEAN rotors Ue on the ground with the STALK cables already

connected. The airship rises from the ground with enough lift to support its

own weight. As it rises lift force is increased (e.g. by dumping ballast) so

that it can lift an increasing number of BEANs suspended below.

As the cable(s) between the airship and the first BEAN become taut the first

BEAN is jerked into the air. (Ascent speed might be ~2 metres/sec.) Shock

absorbers between the BEAN rotor and the central STALK connexion and/or on

any secondary cables supporting the outer parts of the rotor protect the BEAN

from damage. The ascent continues until the second BEAN is lifted into the

air also, and so forth.

During deployment the airship's motors keep it in the correct relative

position to the BEANs on the ground below. Moreover, the secondary propeUors

on the airborne BEANs may be energized (using power from the ground) to

maintain the BEANs in a precisely vertical line, and prevent them from

twisting with respect to one another. In particular, the BEAN which has most

recently left the ground is moved accurately into position with respect to

the one it is about to puU aloft So the whole airborne structure is precisely

controlled throughout deployment.

SUBSTITUTE SHEET

Note that since any electric generator is also a motor, the generators to

which the secondary propeUors are attached can also be used to drive them, by

providing electric power.

If the secondary propeUors are insufficient for lateral flight control (for

instance in the case of twin-bladed primary rotors, whose secondaries can

provide thrust in only one direction relative to the rotor) then the, primary

rotors may have additional propeUors whose function is to provide thrust in

other directions.

Once the whole STALK is airborn and vertical, the STALK is allowed to drift

sideways in tiie wind towards its operational lean angle, and rotation is

started.

The BEANSTALK is recovered by a similar procedure. The secondary propeUors

are used to halt the rotation, and then, they and the airship's propeUors are

used to return the structure to a vertical position above the landing site.

lift from the airship is then steadily decreased (e.g. by venting lifting

gas, or allowing hot air to cool, or by pimping ballast water up the STALK),

so that the structure descends at a steady rate. As each rotor hits the

ground, the shock is absorbed by undercarriage structures (e.g. skids or

wheels) at the tips and/or centre of each rotor.

As during ascent, precise position control of the airborne part of tiie

structure is achieved using the propeUors on both the airship and the rotors.

Thus each rotor is landed in the correct position with respect to those

already on the ground (e.g. adjacent to but not on top of the preceding

rotor). The connecting STALK cables may also be deposited on the ground in

any desired pattern, e.g. a zigzag which does not cross itself or the rotors,

or a loose pile or coil, in which they occupy minimum ground space. Lastly,

the airship itself is recovered.

The STALK may be transported to another site than its launch one. After

initial vertical deployment, the STALK may be detatched from the ground,

allowing the airship to proceed under its own power (e.g. petrol engines) to

the destination site, to which the base of the STALK is secured.

Alternatively, the base of the STALK may be fixed to a surface vehicle (e.g.

an oceangoing tug). This vehicle may provide electric power to the STALK to

drive along the airship and rotors (preventing any excessive forces in the

STALK cable, or twisting, etc. from occurring) so that the vehicle and

BEANSTALK proceed together to the deployment site. The base of the STALK is

then connected to the deployment site (e.g., transferred from an oceangoing

tug to a mooring buoy).

EXAMPLE 15

This Example lists miscellaneous additional features and options.

The structure may take off/land with the help of streams of air provided by

fans or jet tiuusters on the ground. The structure may take off/land with the

help of ground effects a la hovercraft.

The structure may take off/land with the help of magnetic levitation.

Possible flight modes include one in which the main rotor blades provide lift

force without rotating, i.e. like a kite.

Individual rotor blades may connect to the central STALK by tensile wires

only (held taut by centrifugal force during operation). Such blades may be

equipped with control surfaces allowing them to take off and land

horizontally like an aircraft (individually or together). In the latter case,

a circular runway with a rotating central structure may constitute the ground

base. The runway may be conventional, or take the form of a circular canal,

lake, railway track, or maglev track.

Individual blades may be capable of separating and/or joining to the STALK in

mid-air, taking off and landing separately for maintenance while the STALK

continues to function.

A rotor may rise from the ground under its own lift either using its

secondary propeUors to provide helicopter¬ like vertical takeoff; or

accelerating the primary horzontally until it generates lift like an aircraft

wing for horizontal takeoff; or by tilting a non-rotating primary so that it

lifts in the wind like a kite; or by spinning the primary so that it itself

generates a heUcopter type lift; or by spinning the primary tilted with

respect to tiie prevailing wind so that it provides autogyro-type lift (the

secondaries may provide any necessary lateral force(s) in each case.) These

flight modes may also be used in circumstances (such as in light winds) where

the rotors must be kept aloft, but not generate power or cause high tensile

forces in the STALK tether.

The main rotors may have an upwardly arched form so that in wind die tips are

puUed apart from one another, preventing a compressive force in the rotor

arising due to the tension in the secondary tethers.

The blades of each main rotor may be connected by wires running approximately

circumferential to the rotor (from blade tip to blade tip, and or

intermediate points on each blade), for additional strength and rigidity.

The secondary propeUors may themselves be equipped with tertiary propeUors

(and so on) for power extraction; e.g. to provide power at the highest

possible revs.

The structure may take off or land from water (e.g. the sea surface).

Parachutes may assist an unpowered 'splashdown'.

The BEANSTALK structure may weU make use of active control systems to guide

it during deployment, recovery, and power-generating operation. These systems

may use sensors to detect relevant parameters (e.g. rotor position and

orientation, wind speed, etc.), situated on the ground below and/or on any

parti's) of the structure, including on each rotor blade and also on the

airship. Control may be provided by a single computer (e.g. on the ground

SUBSTITUTE SHEET

below or on the airship), or micro-processors situated on each rotor (which

may have faciUties for communicating with one another and/or with a main

controlling computer) or any combination or multiplication of such systems.

Individual rotors and or the system as a whole may be intrinsically unstable,

stability being provided by the active control system(s).

The rotating STALK tether may be clad in counter-rotating ailerons to

minimize the wind force on it The STALK may have an upper rotating part

(including the rotors) joined at a rotating collar to a lower part which does

not rotate. This lower part may be given an aerodynamicaUy shaped

cross-section, to minimize wind force on it In eitiier case some controllable

ailerons may be provided so that the movements of tiie STALK tether itself

may be actively controUed.

The rotor blades may be hinged so that during deployment they hang parallel

to the STALK and swivel outward under centrifugal force when rotation is

initiated. In this case tiie blades may be all-tensile and very numerous

(e.g. strips of shaped plastic deploying into a Maypole-like structure). The

strips may be each of slightly different length so that the secondary

propeUors at their tips do not collide with one another during deployment The

strips may be controUed by twisting them at either end. The ends of the

hinged blades (and/or intermediate points on the blades) may be connected by

tensile wires so that the blades are forced into a rigid cone under

centrifugal force.

A BEAN rotor may be deployed in the sky as an all-tensile structure which is

initiaUy folded (e.g. as a slotted parachute which bells out and starts

rotating under wind force).

The secondary propeUors may be attached to the rotor tips, or any other part

of the rotors, or deployed from the rotors (e.g. on tensile tethers deployed

further outward by centrifugal force).

The system of using secondary propeUors to extract energy from a main rotor

at higher revs/lower torque than could be done directly can be appUed to an

otherwise conventional ground-based rotor of any type. This includes

horizontal-axis turbines and also vertical-axis designs such as the Darrieus.

The secondary propeUors may have the effect of diminishing the vorticity

introduced into the airstream due to the rotation of the primary. This may

increase the efficiency of the system and also cut down interactions between

neighbouring turbines on the same STALK, and between adjacent STALKs.

A single airship may support more than one STALK, or be fastened to the

ground by conventional tether(s) as weU as by energy-generating STALK(s),

particularly to aid deployment and recovery.

A single STALK may be supported by more than one airship.

SUBSTITUTE SHEET

An airship connected to the ground by conventional tether may deploy a

free-hanging STALK of rotors. The rotors, tending to trail behind the

airship, may be flown up to an altitude above the airship itself, e.g. to

intercept higher wind speeds.

Where the secondary propeUors are used to provide lift during deployment and

or recovery of the system, the secondaries may be turned into the verical

plane eitiier simply by turning the whole rotor into this plane (especially

in the case of a two-bladed rotor) or by swivelling the mounts on which the

secondaries are mounted or by swivelling the end parts of the primary rotors.

Single-rotor systems can include a very large rotor (up to — 1 km radius).

The rotor might take the form of an airship, or a structure which is unfolded

or inflated or deployed by centrifugal force from the airship, which may

itself spin with the rotor.

The speed at which the secondary propeUors turn may be controUed by varying

the resistivity (inductance, resistance, capacitance, reactance etc.) of tiie

circuits to which they are connected, especially if they are of fixed-pitch

design.

Consecutive rotors of the STALK may be directly connected by wires which

physically prevent them becoming twisted with respect to one another.

A set of rotor blades which do not aU lie in the same plane may be

cross-connected into a cylindrical structure having effective

three-dimensional rigidity.

Emergency recovery procedures may incude separating the rotors forming a

BEANSTALK from one another by means of explosive bolts, and deploying

parachutes from each rotor tip (or rotor centre) to slow their fall. If the

airship and STALK escape from their ground anchorage, the airship envelope

may be opened by remote control to cause the system to fall into the sea or

onto uninhabited land.

If the airship at the top of the STALK suffers catastrophic failure, a

parachute may be deployed at this point to allow non-destructive recovery of

the rotors.

Cross-wires which support the rotor blades (for example cross-wires from a

node below which support the rotor against aerodynamic force) may attach to

the central STALK cable or to a rigid vertical spar forming part of the

rotor.

Cross-wires may repeatedly bifurcate as they run from the node to their

anchorage points on the rotor. Since aerodynamic forces are ~ 10 times

greater than gravity forces on each rotor, each rotor might have supporting

cross-wires to a node below but not to a node above. Of course not all

cross-wires from a given rotor need

SUBSTITUTE SHEET

terminate at the same node, and there may be a gap between the point where

cross-wires running upward from one rotor meet tiie central STALK support and

that at which the cross-wires running downward from the next rotor above meet

the central STALK support

The secondary propeUors may be oriented in another direction than facing the

local airflow (i.e. approximately tangential to the main rotor). In which

case, aerodynamic surfaces may be employed which divert tiie direction of

tiie local airflow to drive ti e secondaries effectively.

De-icing of the rotor blades may be effected by electric heating or by

circulation of coolant (e.g. heated air) warmed by the electric generators.

This heated coolant may also be used to provide buoyancy, e.g. pumped to a

hot-air airship supporting the BEANSTALK.

Attitude sensors aboard the rotors may include fibre-optic gyros. Position

sensors may make use of a radar system very similar to the precision landing

guidance systems used at many airfields.

Note that two-bladed main rotors occupy little ground area compered to rotors

with 3 or more blades, and so may be landed side by side. Very large 2-bladed

rotors may be transported on a long narrow vessel such as an oceangoing

barge.

In order to minimize the size of the secondary propeUors, while also allowing

the secondaries to rotate with a tip speed below the speed of sound, the

primary rotors may be twin bladed with high tip speed to airspeed ratio and

the secondaries multi-bladed with low tip speed to airspeed ratio.

An alternative method of STALK deployment: The airship may be launched to

altitude while the rotors remain on the ground below. The rotors then climb

the airship tether cable using wheeled attachments which grip it. The rotors

ascend in procession with the main tether (incorprating high strength and

current carrying capacity) shing between them, until the main tether becomes

taut.

An airship at the STALK top may be supplied via a STALK pipeline with

materials including liquids which are then heated to become lifting gas, e.g.

water to steam, liquid methane to gaseous, etc. Control of the lift force of

the airship may also involve cooling lifting gas to liquefy: steam to water,

gaseous to liquid methane, etc. The STALK pipeline may supply combustible

fuel (liquid or gas), as weU as electricity, to power the airship and provide

any auxiliary power or heating required on the rotors or the STALK itself

(e.g. to prevent icing).

If the airship supporting the BEANSTALK has circular symmetry, the top rotor

may be connected to it with tethers connecting the outer parts of the rotor

to the outer parts of the airship, so that the airship is constrained to

rotate with the BEANSTALK without the uppermost part of the cable becoming

twisted. Alternatively, the circular airship may be equipped with propeUors

which force it to rotate at the same speed as the STALK.

SUBST

Note that all primary rotors are normally constrained to rotate at the same

rate (and sometimes constrained not to rotate at aU) so no part of the STALK

becomes twisted. This is normally done by varying the speed and/or pitch of

the secondary propeUors, altering the drag force (sometimes the thrust force)

which they exert on the rotor tips, and tiie amount of power drawn from (and

sometimes supplied to) each set of secondaries.

If the airship does not have circular symmetry, so that it must face into the

wind during BEANSTALK deployment and recovery, then the secondary propeUors

on the rotors may be used to twist the lowest rotor to a different angle to

that it would normally make with the airship above during recovery, so it may

be landed with any desired orientation (e.g. parked parallel to the rotors

already on the ground) irrespective of changes in the airship's orientation.