Hybridizing Fuel Plants/Power Plants

by Kite

- Early old forum holds many notes on the topic.

- Ed: We will aim to gather former notes from anyone on this topic. Invited: links.

- Convert legacy power plants to kite-driveven basis.

- Latest 3r Variation- Legacy Power Plant Reuse

Send

AWE notes and topic replies to editor@upperwindpower.com

NOTES: Technical and Economic Feasibility of Kite-Hybrid Fuel Plants

(Expanding initial response to Max's concerns about hybrid power plant conversion, to realistically face the difficulties, but better detail opportunities.)

Pioneering conversion of a fuel-based power plant to a kite-hybrid is a non-trivial adventure. Various critical factors apply. Site conditions must favor major kite operations; open terrain with good winds, low surrounding population density, and low air traffic. A legacy plant in the early phase of R&D needs promising mechanical features, like ready shaft access to the generators and space to run ropeways in. Economic factors should be favorable; high fuel cost to displace, high electricity price for good revenue, and a depreciated plant otherwise facing phase-out. Social demand and acceptance must be high.

There are endless variations to existing power plants. Early AWE hybrids have a starting advantage to be able to cherry-pick the most favorable cases, starting at modest scale. There already exists an over-running clutch on many large generators for a spin-up starting motor. A fixed-coupled gas or steam turbine might be kept spinning at low aero-drag friction, without fuel, by pumping down a vacuum inside, as an alternative to added clutching. Some compromises can occur, to overcome in future developments.

Massive new gearing or new generators are unnecessary in the most ideal cases. Adding a single clutch to a legacy GW or kW scale generators for trialing kite input is a tiny fraction of new plant investment. Every retrofit will have particular challenges, with every option open to trade-off determination. Even the most awkward starting conditions give way to ingenious industrial mechanics and machinists. The flush end of a mighty shaft can dog-keyed to extend it. The narrowest bit of exposed shaft can be band-sawed to separate a major assembly, with new mounts set into the plant floor to reset pillow blocks. Brilliantly improvised solutions will often prove cheaper than costly capital replacement of fully-amortized heavy machinery, that could still run centuries.

Of course, there will be new hybrid plants, as marvels of innovation, but hybrid-generation advantages will persist for both old and new projects. This principle is inherent in biology, with many energy pathways in living organisms. New plants entail all new capital investment, but the parallel conceptual challenge is how to leverage existing fuel-based plants and grids, especially recent plants in capital-constrained populations like India, where they have become overly invested already. Even a full gen-set replacement of an existing plant should be far cheaper than creating a completely new plant. There are many secondary advantages to power plant reuse, like preexisting land procurement, permitting, grid-connects, airspace and land buffers, continuity of labor force and its social infrastructure.

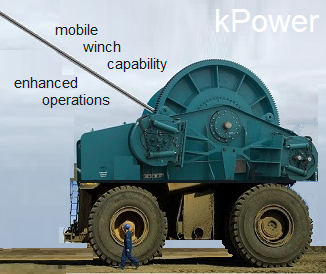

Cableway Fan-in/Fan-out

A cableway kite power input network can be a comparatively modest capital requirement. Industrial mining cableways are models matched the utility plant load scale. Ski resorts, and cable-car and tramway systems are complexity models for kite-hybrid cableway network topology. Sunken cables can be run in slots to avoid surface clutter. Key old tricks include coating sliding wire rope with sacrificial pitch, which both lubricates and protects, and the use of sacrificial hardwood grabbers is also proven. Doppelmayer of Austria is an ideal engineering consultant for this component of a kite hybrid plant.

Favorable Fuel Plant Operational Factors for Hybridization

Fuel plant grid networks are already flexible in practice to closely modulate output based on forecast and actual demand and grid capability to shut down or bring up units. Coal plant units modulate the steam input and natural gas plants are throttled like a jet engine. This variability will match well to kite variability. When forecast wind is favorable, the fuel-side can power down. Across a large regional grid, most wind variability levels out. Kite input should actually enhance grid baseload supply and peaking stability.

The kite hybrid concept also applies to small village diesel plants, ruinous to poor communities in winter in the far North of Canada and Russia. These small plants already require constant supervision, so kite operations can simply build on existing operations.

Matching Kite Operations to Hybrid Generation

The kite aspect must be mature enough to work and pay-off. AWE power kites have many design and operational options to match wind conditions and load demand to existing generators (load motion angular velocity and torque) purely by modulating the kite array and mixing in fuel-side hybrid power. By aggregation of variable sub-units, average power stability finely controllable. Small amounts of bulk system elasticity and momentum further smooths output.

Comparison with Sailing and Kite Sports

Consider how a kite surfer modulates desired kite power fairly precisely within human handling limits, without gearing, by a combination of of kite quiver selection, kite depower input, kite position in the kite window, and playing position on the ground. Similarly Sailors maximize wind power without over-powering by sail changes, furling, and various control inputs.

Comparison of String-based and Gear-based Mechanical Advantage

A particular major insight is that a generalized tri-tether mechanism is itself a fine variable transmission for tunable mechanical advantage ("rigger's angles"), no gears required. Consider an archer's bow-string pulled by a third string "hand", as a triangle of forces that creates high load motion velocity from slower load motion, a dirt-cheap arrangement of string angles actually working better than gearing could.

Summary of Due Diligence Research and State-of-the-Art

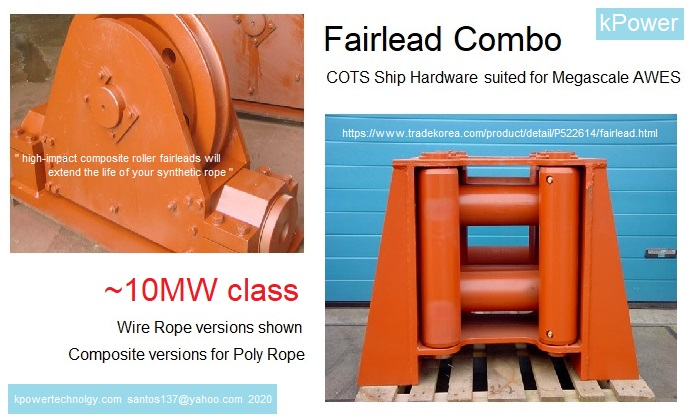

Over the years, developers have initially researched all general issues, including initial consultations with plant experts, and can provide applicable similarity cases and basic equations. Power kite experts vouch for their area of expertise. The proven COTS TRL9 Ship Kite subunit-model and mega-scale multi-r recursive topology is a theoretically sound GW kite power basis.

Scale Prototype Design and Operational Research

On the smallest semi-symbolic kite-hybrid demo scale, simply impinging a rubber tire drive on a mighty generator shaft can input some kite power, reducing fuel load proportionally. Creating small scale prototype hybrid systems, based on cannibalized back-up generators, is going to work, and be great education and fun for student teams. These can both spin-off promptly to small remote communities and vitally inform scaled-up design. The automatic throttling of small fuel plants to match load demand will already accommodate kite input, easing the control requirement.

Related Industrial Kite Applications

Reverse pumped hydro, thermal battery storage, massive dredging of sea dikes, reverse osmosis water desalination, and many other industrial processes can be directly driven by kites. Hybrid power plants will be a source of innovation to radiate into countless industrial niches.

Now

is the time for Faunhofer's Best and Brightest Power Plant Experts to

review, extend, and refine the industrial kite power potential

identified.

=============

- Doppelmayer of Austria is the industry leader in ropeway technology- Material Ropeway | Products

- As Max notes, hydraulic winches favored at the largest industrial scale-

Hydraulic Winch vs. Electric Winch - Winch Manufacturer & Supplier